HOT DIP GALVANIZING TO PROTECT STEEL RUST HAS BEEN USED FOR 150 YEARS.

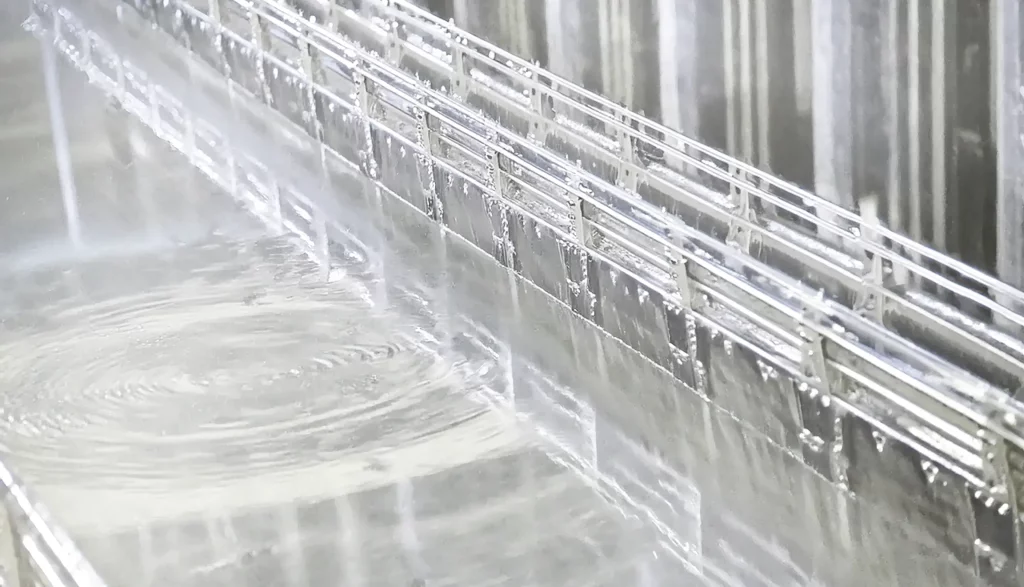

Hot-dip galvanizing is the application of a metallic zinc coating to iron or steel by immersing it in molten zinc (at around 450°). The zinc coating forms an inseparable alloy with the steel. Galvanizing is therefore ideal for all interior and exterior surfaces made of steel or iron and is cost-effective and environmentally friendly. The durability of the hot-dip galvanized product depends on the respective environmental conditions. A zinc coating lasts 20 to 40 years, depending on the environmental conditions and atmosphere.

Facts about hot-dip galvanizing

- Hot-dip galvanizing as steel rust protection has been used for 150 years.

- A temperature range of 440 to 460°C is usually used for hot-dip galvanizing.

- After pretreatment (degreasing, pickling, flux application), the part to be galvanized is immersed in the hot zinc melt, where the metallurgical reaction of the zinc with iron takes place.

- It is possible to galvanize parts that are larger than the zinc basin. This process is called “double dipping”.

- Hot-dip galvanized steel is used in steel construction, bridge construction, as guardrails, markings, power poles, fencing, railings, stops, concrete fittings, forming just as strong a bond with concrete as steel without surface treatment.

- The Brooklyn Bridge upgrade used 23,330 km of hot-dip galvanized wire to create its four main supporting cables. When the bridge was completely renovated after over 100 years, the hot-dip galvanized wires were in perfect condition.

- Hot-dip galvanized steel is more resilient today than it was 20 years ago. The reason is that as a result of stricter laws, the atmosphere is cleaner and contaminated with a lower amount of sulfur dioxide.

- After a certain period of time, reddish-brown spots may appear on the surface of galvanized steel products, which only contain intermetallic phases. However, this is not steel corrosion, as only the very low iron content in the iron-zinc alloy layer oxidizes and forms spots. These stains do not have a negative impact on the rust resistance of the galvanizing.

- Corrosion of steel products causes damage amounting to 3% of gross domestic product in the EU every year. It is estimated that indirect costs can amount to up to 6% of gross domestic product.

The advantages of hot-dip galvanizing

Hot-dip galvanizing is the most effective and reliable system of steel protection. Hot-dip galvanizing offers numerous real advantages that every customer should know:

- sustainable

- resistant

- constant maintenance-free

- cathode protected

- time-safing

- reliable

- inexpensive

- optimal, even in cavities and on the edges

- easy to control

- visually appealing